Drilling geological survey at factory CP Seeds in Dong Nai province

Drilling geological survey at factory CP Seeds in Dong Nai province for adjustment 1/500 and construction permit application. Topographic survey items include drilling 3 boreholes, testing 9 physical and mechanical indicators of soil, water and concrete corrosion, SPT. Let’s learn more in the following.

The purpose of drilling geological survey at factory CP Seeds in Dong Nai province

Geological survey provides factory design data for phase 2 of CP Seeds factory. Providing stratigraphic data at the factory area to design foundations and construction methods.

In addition, we provided data for factory construction permits at the Dong Nai Department of Construction.

Drilling geological survey at factory CP Seeds in Dong Nai province

Amount of work

This is geological survey work at factory CP Seeds

| No. | Explanation | Volume | Unit |

|

| II | Drilling geological surveys | |||

| 1 | Geotechnical survey drill hole: 03 holes – It is expected to drill 20m/hole. When drilling less than 20m and encountering rock, drill another 1m into the rock and stop. – Testing water samples for concrete corrosion (1 sample). – Testing to determine the compressive strength of rock, take 1 sample (if any) – SPT testing on ground soil every 2m/time. – Testing 9 common physical and mechanical criterias according to ISO standards |

3 | Hole | |

| 2 | Transportation fee for moving and returning machinery and equipment, including internal between 3 drill holes | 1 | Contract | |

| 3 | Preparing geological technical investigation reports (5 sets and soft file USB) | 1 | Contract |

Methods of implementation

Geological survey includes external work of geological drilling and internal work (including testing and preparing reports according to regulations)

External work

External work includes locating boreholes using GNSS RTK.

Operating machinery, drilling into soil and rock, taking samples for testing and SPT testing.

Using a specialized sample tube to take soil sampling is a process that uses a metal or plastic tube to collect soil without nearly destroying the sample, in accordance with the requirements for laboratory testing.

- Using static force to push the sample tube into the soil layer (for soft mud or clay) in the borehole, removing soil from the tube wall, determining the sample recovery rate and preserving the sample without being destroyed and loss of natural moisture. For hard plastic clay or more, it is able to used an SPT hammer to drive the sample tube into the bottom of the borehole.

- A portion of the sample will be taken for laboratory testing.

Drilling equipment:

- The drill will be used in sampling. Using the compression force of the Spindle shaft of the drill (or using a hammer) will create a force that compresses the sample tube into the soil.

- The sample tube has a diameter of 76- 90mm and a length of 200- 600mm.

Implementation personnel:

- For each sampling time, personnel are arranged as follows:

- A technician: Responsible for controlling the entire sampling process, sampling depth range, sample labeling and sample rate.

- A driller: Responsible for controlling the drilling machine and taking samples.

- Two assistant workers: Responsible for assisting the driller in performing the above tasks.

Implementation process:

- Step 1: Prepare all necessary equipment and carefully check their condition

- Step 2: The pump cleans the bottom of the borehole while not destroying the sample.

- Step 3: Drop the sampling tube gently down the borehole and into the correct hole of the borehole, ensuring that rock and soil do not enter the sample tube.

- Step 4: Sampling is done by applying a static, non-rotating force to the sample pipe. The driller must adjust the pressure to suit the soil stratigraphy being sampled. The sample length needed is from 200 – 600mm, depending on experimental requirements.

- Step 5: Lift the sampling tube from the bore, clean both ends of the sample, then seal the two ends and label.

Transport and preserve samples

Original form:

- Isolated from outside air by wrapping both ends of the sample tube, then sealing both ends of the sample tube with adhesive tape. Soil samples are labeled to include information such as:

| +The name of construction

+Model number +Name of drill hole +Sampling depth |

+Land description

+Date of sampling +Full name of person taking the sample |

- The intact sample is transported to the laboratory in the shortest possible time under conditions of limited force or sudden change of temperature.

- When returning to the laboratory, samples are arranged in rows on shelves and stored in a room with a temperature not exceeding 20o

Sample is not original:

- Placed in a plastic bag, sealed, labeled and stored in the same way as the unopened sample.

- Samples not tested will be kept in the laboratory for no more than 3 months and will be destroyed after acceptance of the survey..

Internal work

Testing 9 physical and mechanical criteria according to TCVN

1. Natural moisture (W%)

2. Natural respect (g) g/cm3

3. Specific weight (D) g/cm3

4. Grain composition (P%)

5. Flow limit (WL)

6. Plastic limit (Wp)

7. Internal friction angle (j), degree

8.Adhesion force (C), KG/cm2

9. Compaction coefficient (a) cm2/KG

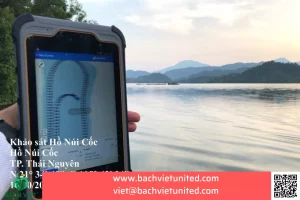

Some images of geological survey at factory CP Seeds